Rotomolded tanks are hollow containers that may hold and store a wide range of contents. They are made of thermoplastic materials. They are renowned for their great tensile strength, impact resistance, and broad design range. Plastic tanks are the most often used object that can be produced using rotational molding, which is a low-cost method that uses rotation, heat, and a mold.Read More…

As a full-service rotational molding company, Roto Dynamics is your source for high quality, custom rotomolded products. Since our inception, we have continued to earn success by closely working with our customers, developing innovative and tailored solutions. We are with you every step of the way, from design and development to production and assembly. For a complete view of our capabilities and ...

We are a custom manufacturer of rotationally molded products. Our state of the art technology creates precise, cost effective and dependable products. Whether your order is large or small, we want to be sure you are satisfied.

Western Industries Plastic Products, LLC, specializes in large-part plastic blow molding. We provide expertise and services in product design, process improvement, and product assemblies. We offer our customers comprehensive services and turnkey opportunities to achieve their specific project goals. We can assist with: R&D, product design, product improvement, and secondary-fixture design. For...

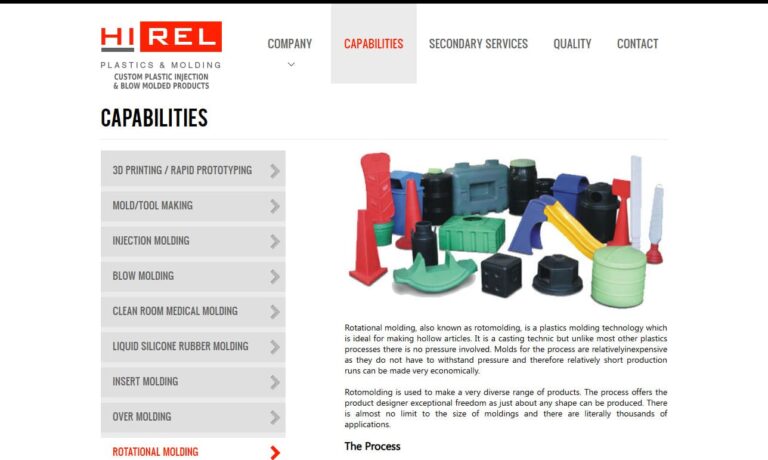

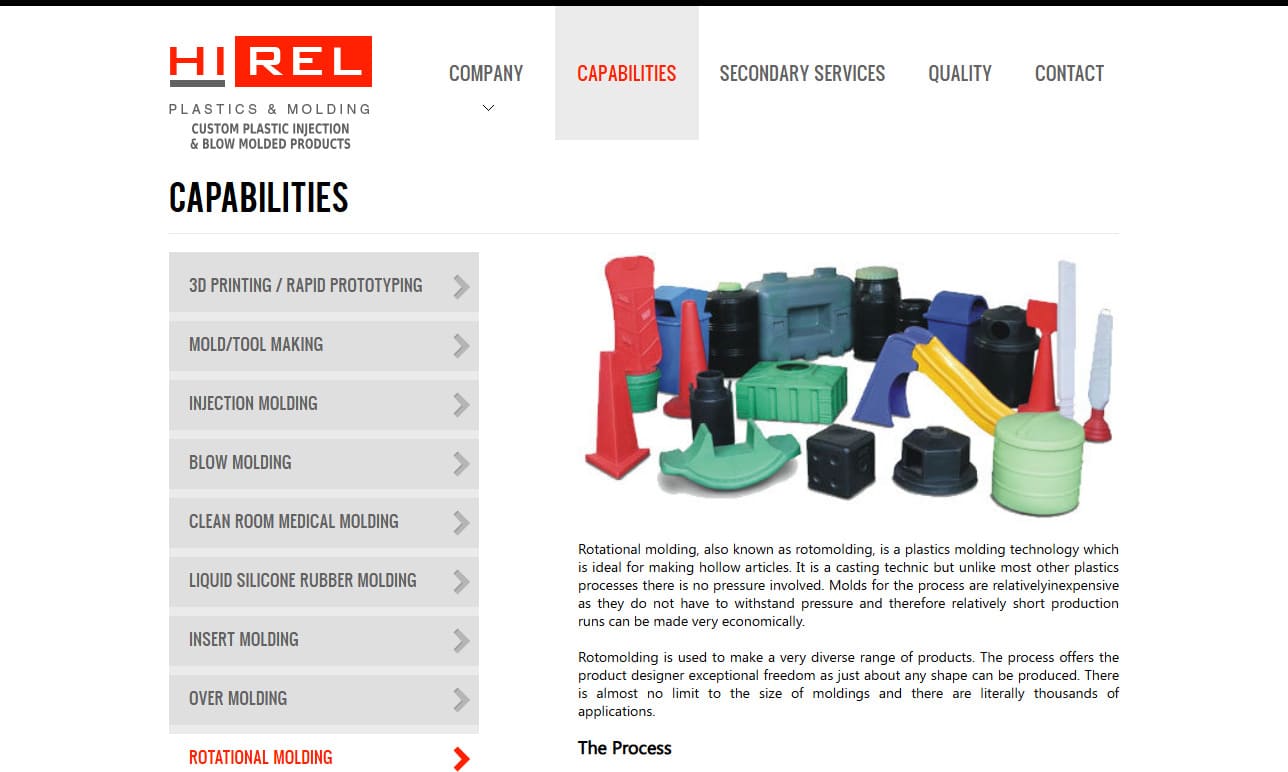

At Hi-Rel Plastics & Molding, we specialize in delivering high-performance solutions through advanced rotational molding. As a team deeply committed to precision and innovation, we bring decades of experience to the design and manufacture of custom rotationally molded products.

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

More Rotomolded Tank Companies

Rotomolding Process of Tanks

In the process of rotomolding a tank, a heated hollow is filled with a charge or shot weight of material. Additionally, it is often slowly rotated across the two parallel heat axes, allowing the softened material to disseminate and adhere to the mold walls. The mold rotates continuously during the heating phase to prevent drooping or distortion and during the cooling phase to maintain the thickness throughout the portion.

The mold is mounted in the oven, which has natural gas burners heating it, and bolted at the dividing line. At 4 to 12 rpm, it is hydraulically rotated. Polyethylene is added layer by thin layer as the plastic melts. When the plastic has fully formed and hardened, it adopts the shape of the mold, which is then taken out of the oven. Once the tank has cooled, the mold is removed to reveal the finished item. In a rotomolding setup, expert manual labor is required. For instance, special workers are required to open and close the molds during the rotomolding process. The die's opening and closing require strenuous manual labor.

Materials Used to Make Rotomolded Tanks

Rotationally-molded tanks can be created using a variety of thermoplastic substances, such as polyethylene, polypropylene, Halar, and polyvinylidene fluoride, all of which are high-purity plastics. Depending on the application of the product, additive materials are frequently added to the plastic resin to improve attributes including strength, moisture, chemical, and temperature resistance, color, and flame retardancy.

Plastic tanks are among the largest goods made using rotational molding. As a result, producers use the biggest rotomolders to make them. They need a lot of room, a place where intense heat can be generated, and a place to cool things off. If necessary, the rotational molding machine will need room to turn around two separate axes in each of these locations.

The polymer resin is usually in fine-powder form when making the tanks so it is easier to get into all the nooks and crannies of the tank-shaped mold. Even distribution of the plastic can be a difficulty because the process is conducted at low speeds and low pressure. However, sophisticated designs like two-compartment tanks are feasible if the plastic granules are fine enough. Rotomolded tanks can store anything from a few gallons to several thousand gallons and are made to be either horizontal or vertical in configuration.

Advantages of Rotomolding

- Low operating pressures enable the creation of rotomold tooling from inexpensive metals like aluminum.

- Wall thickness is constant thanks to the mold's continuous rotation during the heating and cooling cycles.

- Complex double-walled open containers can be made using the double-wall construction method without further processing.

- High durability: pieces are molded as a single, solid piece, avoiding the necessity for weakening connection methods like welding and joint fabrication.

- High stability: Since the molding material is not subjected to external pressure, it is more stable and there is less chance that the finished item will have flaws.

- Strength: Rotomolding produces thicker corners, lowering the likelihood that they may fail at certain stress-concentration places.

- Aesthetics: Surface finishes like fine-detail textures, logos, emblems, and letters are easily accommodated by the soft metal utilized for the rotomold tooling.

Disadvantages of Rotomolding

- High cycle times: rotomolding can take up to three hours to complete one part at eight rotations per minute.

- Limited material choices: Poly-based resins are the only materials that can be utilized for rotomolding since they can easily be transformed from granules to a fine powder and have great thermal stability.

- High cost of raw materials: The cost of adding the necessary additives, the expense of grinding the material into a powder, and the high criteria for thermal stability all contribute to high material costs.

- Low repeatability: Due to a lack of repeatability, the rotomold tooling's soft metal must be repaired or replaced after 3,000 cycles and may result in quality problems.

- High labor costs: rotomolding requires more labor intensity than equivalent production because mechanization and automation have not yet been implemented.

Choosing the Right Rotomolded Tank Manufacturer

To make sure you have the most beneficial outcome when purchasing rotomolded tanks from a rotomolded tank manufacturer, it is important to compare at least 5 companies using our list of rotomolded tank manufacturers. Each rotomolded tank manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rotomolded tank business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple rotomolded tank businesses with the same quote.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services