Rotationally molded plastics are thermoplastic products fabricated through the rotational molding process, or rotomolding. A thermoplastic is a plastic material that will soften when repeatedly heated and cooled. The rotomolding process is simple and inexpensive, involving only a revolving mold and high heat. Rotationally molded plastics are hollow, with the high tensile strength and uniform wall thickness due to single piece construction. Read More…

As a full-service rotational molding company, Roto Dynamics is your source for high quality, custom rotomolded products. Since our inception, we have continued to earn success by closely working with our customers, developing innovative and tailored solutions. We are with you every step of the way, from design and development to production and assembly. For a complete view of our capabilities and ...

We are a custom manufacturer of rotationally molded products. Our state of the art technology creates precise, cost effective and dependable products. Whether your order is large or small, we want to be sure you are satisfied.

Western Industries Plastic Products, LLC, specializes in large-part plastic blow molding. We provide expertise and services in product design, process improvement, and product assemblies. We offer our customers comprehensive services and turnkey opportunities to achieve their specific project goals. We can assist with: R&D, product design, product improvement, and secondary-fixture design. For...

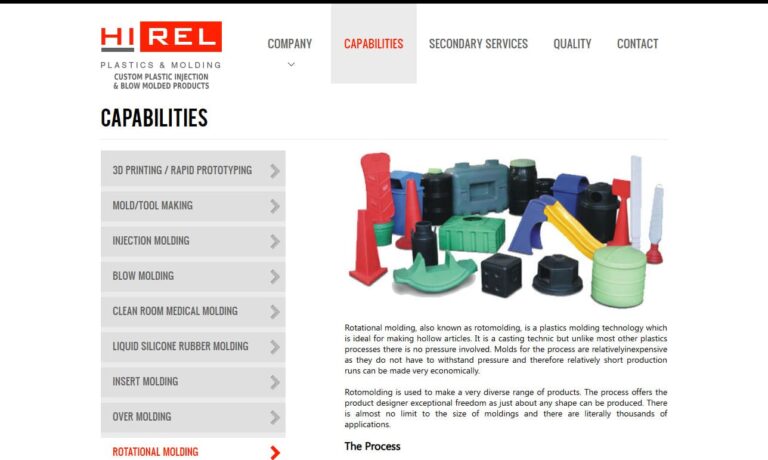

At Hi-Rel Plastics & Molding, we specialize in delivering high-performance solutions through advanced rotational molding. As a team deeply committed to precision and innovation, we bring decades of experience to the design and manufacture of custom rotationally molded products.

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

More Rotational Molding Companies

Applications

Customers consistently appreciate rotomoulding for the exceptional quality and reliability of its rotomolded products, as well as the cost-effectiveness of its tooling and manufacturing processes. Rotational molding, also known as rotomolding or rotocasting, produces plastic parts with high tensile strength, uniform wall thickness, and seamless, single-piece construction. These features ensure durability, leak resistance, and superior product performance across various applications.

Rotationally molded plastics have become an industry standard in sectors such as road construction, agriculture, plumbing, sporting goods, packaging, material handling, automotive, toy manufacturing, wastewater management, pharmaceuticals, food and beverage processing, fuel and oil storage, chemical handling, and marine manufacturing. Whether creating large, durable storage tanks for water treatment plants or precise, lightweight safety equipment for sports, this process offers unmatched versatility and adaptability.

Are you exploring how rotational molding can solve your industry’s unique challenges? Discover tailored rotomolding solutions for:

- Agriculture: Water and chemical tanks, livestock feeders, pesticide bins.

- Automotive: Fuel tanks, air ducts, protective housings, bumpers.

- Medical & Pharmaceuticals: Sterile containers, diagnostic equipment housings, transport cases.

- Consumer Goods: Outdoor furniture, storage containers, playground equipment.

- Industrial & Material Handling: Bulk containers, shipping pallets, hazardous material drums.

- Marine: Kayaks, buoys, dock floats, marine storage units.

- Construction & Infrastructure: Traffic barriers, safety cones, manhole liners, septic tanks.

Looking for a specific application or industry use case? Contact a rotational molding expert or browse our list of top rotomolding companies for more information and custom solutions.

Products Produced

Rotomolding is a highly adaptable manufacturing process, enabling the production of an extensive variety of products and components. In sports and recreation, rotomolding creates canoes, kayaks, playground slides, footballs, and sports helmets—delivering durability, impact resistance, and lightweight performance.

Beyond recreational equipment, the technique is essential for producing industrial-grade goods such as large plastic vessels and storage tanks (including chemical, water, and septic tanks), safety cones for traffic management, oversized trash containers, hollow bins for logistics, outdoor and patio furniture, beverage dispensers, and insulated coolers.

Other prominent rotomolded products include:

- Rainwater harvesting tanks

- Trash and recycling bins

- Fuel and oil tanks for vehicles and machinery

- Shipping containers and material handling totes

- Protective cases for sensitive equipment

- Marine buoys and floats

- Custom industrial housings and enclosures

Curious about whether rotomolding is right for your product idea? Ask these questions:

- Is my product hollow or requires a seamless, leak-proof design?

- Does it need to withstand harsh chemicals or outdoor environments?

- Is lightweight strength a priority?

If the answer is yes, rotational molding may be the ideal choice.

History

The origins of rotational molding trace back to 1855, when British inventor R. Peters pioneered the first rotational molding process to manufacture artillery shells and hollow vessels with uniform density and wall thickness using biaxial rotation and heat. This foundational concept set the stage for future advancements in hollow plastic manufacturing.

The technique remained largely dormant until 1905, when American innovator Fred A. Voelke explored rotational molding for crafting hollow wax objects. Shortly after, in 1910, G.W. Perks and G.S. Baker used the method to create hollow chocolate eggs—a testament to the process’s adaptability across materials and industries.

In the 1920s, R.J. Powell leveraged rotational molding to shape plaster of Paris, a material blend of lime, sand or cement, and water. Named for the gypsum-rich region of Montmartre, Paris, plaster of Paris marked one of the earliest materials processed via this technique.

Fast forward to the 1940s and 1950s, the industry underwent a technological leap with the introduction of plastic rotational molding. This era saw the creation of hollow plastic toys, especially doll heads, using rudimentary machines assembled from automotive parts and powered by gas burners. Molds made from copper and nickel were cooled in water baths, and PVC plastic dominated production thanks to its workability and availability.

By 1976, the growing importance of rotomolding led to the founding of the Association of Rotational Molders (ARM) in Chicago. ARM quickly became a global trade organization, fostering innovation and sharing knowledge among members from 58 countries. The late 20th century brought about the introduction of advanced polymers such as polycarbonate and nylon, revolutionizing the manufacture of industrial molds, water tanks, and fuel tanks through greater strength, chemical resistance, and performance.

During the 1980s, breakthroughs in automated control and monitoring of the cooling process—spearheaded at Queen’s University Belfast—transformed the precision and efficiency of rotomolding operations. Today’s manufacturers continue to innovate with enhanced materials (such as UV-resistant polyethylene, flame-retardant additives, and antimicrobial plastics) and cutting-edge process controls, enabling the production of safer, stronger, and more complex products.

Wondering how modern advancements in rotational molding could benefit your next project? Explore the latest trends in rotomolding materials and technology or speak with a leading supplier for expert guidance.

Materials Process

Rotational molding accommodates a wide range of plastics and polymers, each selected for its unique properties and performance characteristics. The most common materials include polyethylene (PE), cross-linked polyethylene (PEX or XLPE), high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and polyvinyl chloride (PVC). These materials are chosen for their balance of strength, flexibility, chemical resistance, and cost-effectiveness.

Polyethylene (PE)

Polyethylene is the most widely used plastic in rotomolding due to its lightweight nature, high impact resistance, and excellent ductility. It is available in various grades (such as LDPE, HDPE, and LLDPE) to suit different applications. Polyethylene’s low modulus of elasticity makes it ideal for products like tanks, bins, and bottles that require flexibility and toughness. Key benefits: affordability, ease of processing, and recyclability.

Cross-Linked Polyethylene (XLPE)

Cross-linked polyethylene offers superior impact strength, environmental stress-crack resistance, and abrasion resistance. Its molecular structure makes it well-suited for applications exposed to extreme temperatures or harsh chemicals, such as underground storage tanks, chemical process containers, and fuel tanks.

High-Density Polyethylene (HDPE)

HDPE stands out for its excellent performance in cold weather, chemical resistance, and high molecular weight. Products made from HDPE exhibit superior gloss, rigidity, and internal finish, making them suitable for high-performance containers, automotive components, and outdoor installations.

Linear Low-Density Polyethylene (LLDPE)

LLDPE provides a balance of flexibility, toughness, and processability. Rotomolded parts made from LLDPE feature exceptional fit and finish, robust impact resistance, and enhanced tensile strength. Common uses include playground equipment, flexible tanks, and soft-sided containers.

Polyvinyl Chloride (PVC)

PVC, or vinyl, is valued for its outstanding chemical resistance, transparency, weatherability, and electrical insulation properties. Available in both rigid and flexible forms, PVC is used in applications ranging from piping and cable insulation to clear containers and medical devices.

Other specialty materials used in rotational molding include nylon (for high-heat and abrasion resistance), polycarbonate (for optical clarity and toughness), polypropylene (for chemical resistance), and flame-retardant or UV-stabilized resins for specialized industrial applications.

Not sure which material is right for your application? Compare rotomolding material options based on chemical compatibility, temperature requirements, structural needs, and regulatory compliance to ensure optimal performance and longevity.

Process Details

- Charging: The process starts by loading raw thermoplastic powder or granules into a precisely engineered metal mold, which is mounted on rotating arms called spindles. Material selection may include polyethylene, polypropylene, PVC, or custom-engineered resins, depending on the end-use requirements.

- Heating & Rotation: The loaded mold is transferred to a high-temperature oven, where it is heated and rotated biaxially—simultaneously spinning on both horizontal and vertical axes. This ensures the molten plastic uniformly coats the interior surface of the mold, resulting in a seamless, void-free part. This low-pressure process allows for the inclusion of additives such as UV stabilizers, flame retardants, or anti-static agents to enhance final product properties.

- Cooling: Once the plastic has fully melted and achieved even distribution, the mold is moved into a cooling chamber. Here, the part is gradually cooled and solidified, typically using a combination of air and water sprays over approximately 20–30 minutes. Controlled cooling prevents warping and maintains precise tolerances.

- Demolding: The last phase involves opening the mold and carefully removing the finished part. Operators may perform post-processing steps such as trimming, drilling, or adding inserts, depending on the product design.

Note: Manufacturers can either source polymer materials externally or conduct poly processing and compounding in-house for greater quality control. The rotomolding process is highly customizable, supporting both short production runs and large-scale manufacturing with minimal tooling costs.

Have questions about the rotomolding production cycle? Explore detailed process guides or request a consultation to optimize your manufacturing workflow.

Design

Designing a rotationally molded part involves a careful balance of application needs, product functionality, and manufacturing constraints. Engineers consider key factors such as required strength, thermal stability, impact resistance, flexibility, and environmental exposure. Additional considerations include product color, surface texture, branding requirements, and regulatory compliance (such as FDA, NSF, or ASTM standards).

Material selection is critical—designers choose from a range of plastic resins and additives to achieve the desired mechanical, chemical, and aesthetic properties. Rotomolding allows for the integration of advanced features such as threaded inserts, molded-in graphics, multi-wall construction, and custom reinforcements. This makes it ideal for producing complex, customized, or branded parts without the high costs associated with injection molding tooling.

For custom rotomolded solutions, manufacturers often develop bespoke molds tailored to unique product geometries. Options include variable wall thickness, integrated hinges or handles, embossed logos, and multi-component assemblies. Advanced CAD modeling and prototyping ensure that designs meet stringent performance and quality requirements before entering production.

Considering a custom rotomolded part? Ask these key design questions:

- What load-bearing or mechanical properties are required?

- Will the part be exposed to chemicals, UV, or weather extremes?

- Which regulatory standards must be met?

- What branding or identification features are needed?

Consult with an experienced rotomolding designer to turn your concept into a manufacturable, cost-effective reality.

Machinery Used

Rotational molding relies on specialized rotomolders—industrial machines designed for precise, repeatable production of hollow plastic products. A typical rotomolding system consists of four core components: an oven (heating chamber), molds, mold spindles (rotating arms), and a cooling chamber.

Oven: Delivers consistent, uniform heat to melt the plastic material inside the mold.

Mold: Crafted from cast or fabricated metals, molds define the final product’s shape, surface finish, and detailing.

Mold Spindles: Secure the molds and provide controlled, biaxial rotation for even material distribution.

Cooling Chamber: Reduces mold temperature, solidifying the part and preserving dimensional accuracy.

Modern rotomolding machines come in several configurations, each suited to particular product types, production volumes, and facility layouts:

Carousel Type

Carousel rotomolders are the most common bi-axial machines, offering four or six stations. Their synchronized arms allow heating, cooling, loading, and unloading to occur simultaneously, maximizing throughput and efficiency for high-volume production runs.

Clamshell Type

Clamshell rotomolders use a single chamber for both heating and cooling, rotating molds along multiple axes with programmable control. Their compact footprint and cost-effectiveness make them ideal for small to medium batch sizes and custom projects.

Rock and Roll Type

Rock and roll rotomolders feature elongated heating chambers, optimized for manufacturing long, narrow parts (such as kayaks or piping). They enable either single-arm or dual-arm (shuttle) operation for added flexibility and increased output.

Vertical Type

Vertical rotomolding machines utilize stacked heating and cooling chambers and are loaded/unloaded from the front. Their design saves space and energy, making them suitable for plants with limited floor area or specialized product lines.

Shuttle Type

Shuttle rotomolders move molds between separate heating and cooling stations, enabling rapid cycle times for large or complex products. Their modular design offers high customization and scalability for growing production needs.

Not sure which rotomolding machine fits your project? Compare machine types based on product size, shape, batch volume, and facility layout to select the optimal solution.

Variations and Similar Processes

While rotational molding excels at producing seamless, hollow plastic products, several other plastic forming methods are often evaluated for similar applications. Understanding these alternatives helps you choose the most efficient and cost-effective process for your needs.

Blow Molding

Blow molding is primarily used to manufacture hollow plastic parts like bottles, jugs, and containers. In this process, molten plastic is formed into a parison (tube-shaped preform), which is then clamped into a mold and inflated with air. The expanding plastic conforms to the mold’s inner contours, creating lightweight, uniform-walled products. Blow molding offers rapid cycle times and is ideal for high-volume, standardized packaging production.

Injection Molding

Injection molding is a versatile process suitable for both plastics and metals. It involves injecting molten material into a precision-machined mold under high pressure. This method excels at producing parts with complex geometries, fine details, and tight tolerances—such as threaded caps, intricate housings, and automotive components. Injection molding is faster than rotational molding and best suited for mass production of small to medium-sized items.

Extrusion

Extrusion differs from molding by forcing molten plastic through a shaped die, creating continuous products with uniform cross-sections (e.g., pipes, tubing, window frames). Extrusion is ideal for producing long lengths of profile shapes, especially from materials that may be brittle or require specific surface finishes. The process is continuous and highly efficient for large-scale production.

Considering different manufacturing processes? Compare rotational molding vs. blow molding, injection molding, and extrusion to determine the best fit for your product, budget, and performance requirements.

Benefits

Rotational molding delivers distinct advantages over other thermoplastic forming methods, making it the preferred choice for many custom and industrial applications.

- Cost-Effective Tooling: Rotomolding employs low-pressure molds, significantly reducing tooling and equipment expenses compared to injection or blow molding. This makes it ideal for prototyping, short production runs, and custom products.

- Design Flexibility: The process accommodates intricate shapes, varying wall thicknesses, internal structures, and integrated features—without expensive mold modifications.

- Material Versatility: Supports a broad range of polymers and specialty additives for tailored performance, including UV stability, flame retardancy, food-grade compliance, and more.

- Seamless, Leak-Proof Construction: Produces single-piece, hollow products with no welds or seams, enhancing strength, safety, and durability—critical for tanks, containers, and pressure vessels.

- Efficient Color Changes: Quick transitions between different colored plastics are possible, reducing downtime and minimizing material waste.

- Lightweight & Durable: Rotomolded parts are strong yet lightweight, easy to handle, and highly resistant to impacts, chemicals, and environmental exposure.

- Regulatory Compliance: Products can be manufactured to meet FDA, NSF, or other industry standards—essential for food, beverage, pharmaceutical, and medical applications.

- Customization: Easily incorporate logos, graphics, textures, and personalized features—perfect for branded, retail, or specialty products.

Is rotational molding right for your next project? Weigh the benefits and limitations compared to other plastics manufacturing methods, or ask a rotomolding specialist for a detailed ROI analysis.

How to Choose the Right Manufacturer

Choosing the best rotational molding company is crucial for achieving quality, efficiency, and cost-effectiveness in your production. Here’s a step-by-step approach to help you evaluate and select the right rotomolding partner:

- Define Your Requirements: Compile a detailed list of your product specifications, application needs, material requirements, regulatory standards, and budget constraints.

- Research Qualified Companies: Browse our curated list of leading rotational molding companies and review their capabilities, certifications, and industry experience.

- Compare Services and Capabilities: Look for manufacturers that offer comprehensive services—including design support, prototyping, material selection, custom tooling, secondary operations, and logistics.

- Check Certifications and Compliance: Ensure the company meets necessary quality standards—such as ISO certification, FDA registration, or industry-specific accreditations—to guarantee product safety and regulatory compliance.

- Request Quotes and Proposals: Shortlist three to four manufacturers that align with your requirements. Contact each for detailed quotes, lead times, and production capabilities. Discuss options for custom rotational molding, volume discounts, and delivery schedules.

- Evaluate Communication and Support: Assess responsiveness, technical expertise, and willingness to collaborate throughout the design and manufacturing process. Reliable partners provide transparent communication and proactive problem-solving.

- Make Your Selection: Choose the manufacturer who offers the best balance of quality, cost, service, and expertise—then initiate your project with confidence.

Looking for advice on selecting a rotomolding partner? Contact our industry experts or request a consultation to match your needs with the top-rated rotational molding companies in your region.

Whether you’re developing a new product, scaling production, or seeking cost-saving alternatives to traditional manufacturing, rotational molding offers a powerful combination of flexibility, efficiency, and performance. Explore our resources, case studies, and company listings to get started—or reach out today for personalized recommendations and support.

What is rotational molding and what are its main advantages?

Rotational molding, also known as rotomolding or rotocasting, is a plastics manufacturing process that creates hollow, durable, and seamless components with uniform wall thickness. Its main advantages include cost-effective tooling, design flexibility, support for a wide range of materials, seamless leak-proof construction, efficient color changes, and ease of customization for various applications.

What types of products are commonly made using rotational molding?

Common products include storage tanks, water and chemical bins, automotive fuel tanks, traffic barriers, trash and recycling containers, playground equipment, kayaks, buoys, outdoor furniture, and medical transport cases. The process is also popular in industries like agriculture, automotive, marine, pharmaceuticals, and consumer goods.

Which materials are most frequently used in rotational molding?

The most frequently used materials in rotational molding are polyethylene (PE), including HDPE, LLDPE, and cross-linked polyethylene (XLPE), as well as polyvinyl chloride (PVC), polycarbonate, nylon, polypropylene, and specialty resins designed for UV stability, chemical resistance, or flame retardancy.

How does the rotational molding process work?

The process involves loading plastic powder into a mold, heating and rotating the mold on biaxial spindles inside an oven, cooling it so the plastic hardens in the desired shape, and then removing the finished part. Additives can be incorporated for enhanced performance, and the process supports both small runs and large-scale production.

What are the main types of rotomolding machines?

Main machine types include carousel, clamshell, rock and roll, vertical, and shuttle rotomolders. Each type is suited to different batch sizes, product shapes, facility layouts, and production volumes, offering various levels of efficiency and flexibility for different manufacturing needs.

How should I choose the right rotational molding manufacturer for my project?

To select the right manufacturer, define your requirements, research qualified companies with relevant certifications, compare their services and capabilities, request quotes and detailed proposals, and evaluate their communication and support. Choose the partner that best meets your needs for quality, expertise, and cost-effectiveness.

How does rotational molding compare with other plastic forming techniques?

Rotational molding stands out for its ability to produce large, hollow, seamless parts with minimal tooling costs. Compared to blow molding, injection molding, and extrusion, rotomolding is often preferred for low-to-medium production volumes, complex shapes, and heavy-duty applications, though it generally has longer cycle times than injection or blow molding for small parts.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services