When creating various plastic items in high demand, using a rotational molder has many benefits. A moving mold can be highly beneficial when creating plastic objects and opens up a wide range of plastic fabrication options. By regulating cycle times and improving the effectiveness of the thermoplastic casting process, rotational molders also lower manufacturing costs. Products made with rotationally molded plastic can be tailored to various thicknesses, material compositions, configurations, and product requirements. Read More…

As a full-service rotational molding company, Roto Dynamics is your source for high quality, custom rotomolded products. Since our inception, we have continued to earn success by closely working with our customers, developing innovative and tailored solutions. We are with you every step of the way, from design and development to production and assembly. For a complete view of our capabilities and ...

We are a custom manufacturer of rotationally molded products. Our state of the art technology creates precise, cost effective and dependable products. Whether your order is large or small, we want to be sure you are satisfied.

Western Industries Plastic Products, LLC, specializes in large-part plastic blow molding. We provide expertise and services in product design, process improvement, and product assemblies. We offer our customers comprehensive services and turnkey opportunities to achieve their specific project goals. We can assist with: R&D, product design, product improvement, and secondary-fixture design. For...

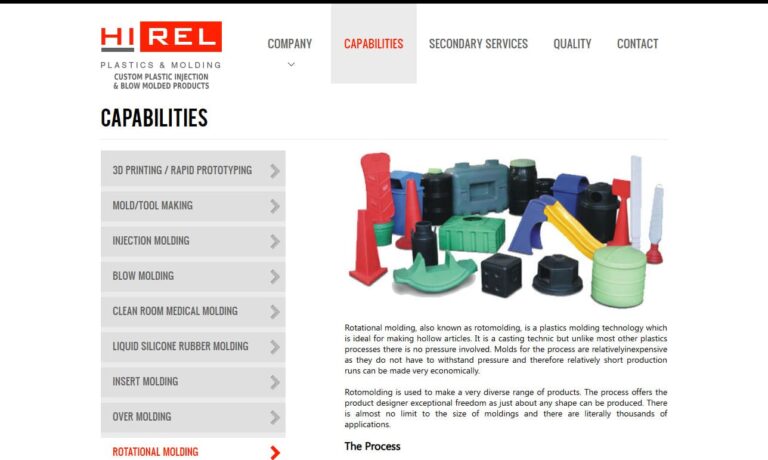

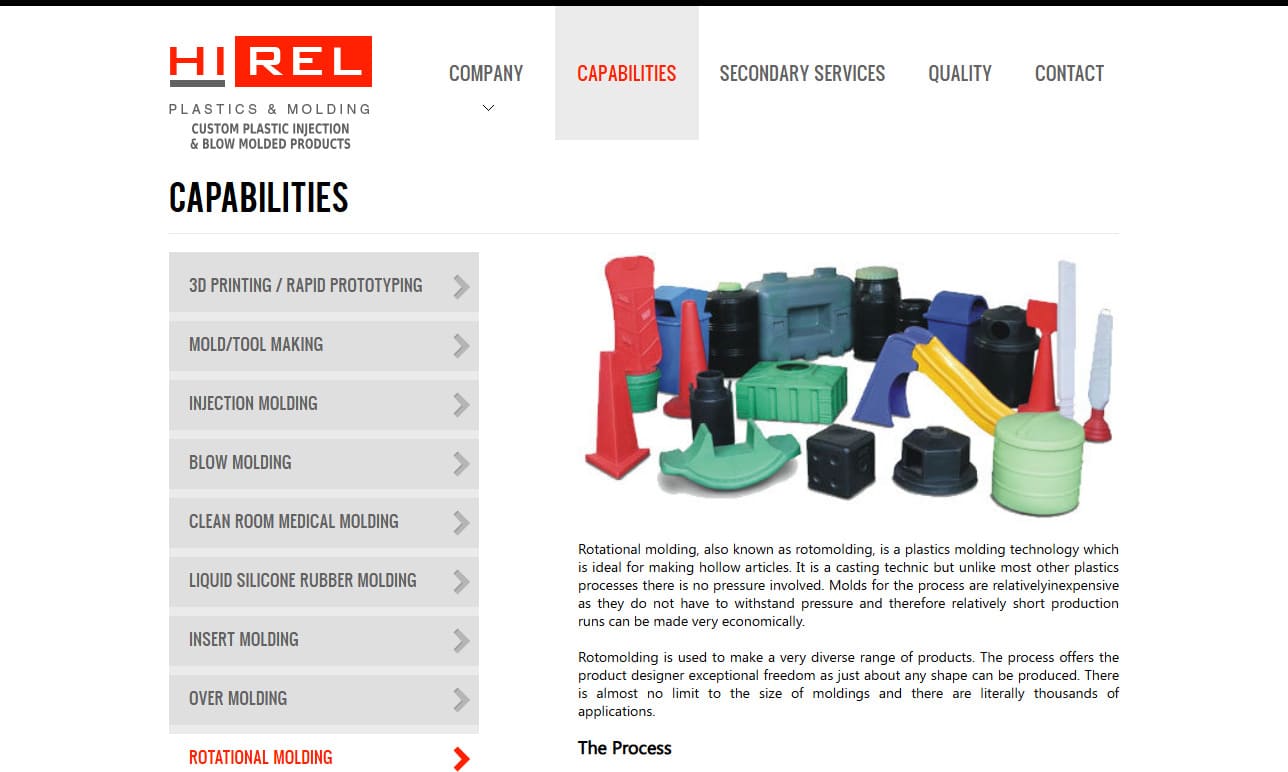

At Hi-Rel Plastics & Molding, we specialize in delivering high-performance solutions through advanced rotational molding. As a team deeply committed to precision and innovation, we bring decades of experience to the design and manufacture of custom rotationally molded products.

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

More Rotational Molder Companies

Rotational thermoplastic molding is also used to address a wide range of temperature, melt flow, and shrink rate problems. This sector is always undergoing innovation and improving efficiency due to research and development. Rotational molds cost less upfront because roto casting fills a mold using centrifugal force and gravity. This method is particularly true compared to other molding techniques like injection molding and blow molding.

For rotational molding to consistently create high-quality parts, several interrelated factors and details must be configured properly: the specific part design, the plastic selection, the design and construction of the mold, and finally, the rotational molding procedure itself. The end-use criteria typically include guidelines describing the part's design, construction material, and measurements.

However, every design must also be useful and affordable. The part's design determines the cost of mold creation and the operation process. Due to their high melting temperature and viscosity, fluoropolymers, another type of product used in rotational molding, place extra constraints on the design of the process and the component.

Rotational Molding Process

Large hollow, seamless, and double-walled items are produced using the rotational molding plastic casting technique. The rotational molding process has three stages involving a heating chamber, a mold on a rotating frame, and a cooling chamber. Specially created rotational molds can produce both single and double-walled goods.

In this process, one of the polyethylene resins serves as the primary raw material for rotational molding and is placed into the mold at the start of the procedure. The mold is heated while being rotated in the heating chamber. The mold's frame can rotate the mold around its axis of rotation. The resin is distributed over the inside surface of the mold as it spins, giving the completed item a uniform thickness across its surface.

A predetermined amount of time is required for the mold to transition, i.e., from the heating chamber to the cooling chamber. The liquefied melted resin is allowed to cool before the plastic product is expelled from the mold. Rotationally molded goods are of the finest caliber and are renowned for their toughness and longevity.

Rotational Molders Available

Cast Molds: One of the rotational molds that are most frequently utilized. Both big and small parts can be made with cast molds. Cast molds frequently create components with intricate designs and a lot of detail. To include design modifications, they are easily adaptable. The textures and shapes of existing objects can be "pulled" with the help of these molds. This casting method works excellently for parks with intricate curving or distinctive characteristics.

Acrylic Molds: These molds work by adding epoxy and then curing with a liquid polyester that uses thermosetting. These epoxy molds, like cast molds, are excellent for small batches or prototype designs that may require modifications before their final forms are produced.

CNC Molding: When high precision is necessary, CNC molders are used. However, they often cost a lot of money and are only applied in unique situations.

Rotational molding products are mostly large plastic products such as:

- Oversized containers

- Vehicle part components

- Animal habitats

- Traffic cones

- Recycling bins

- Play area slides

Applications of Rotational Molders

- Rotational molding is the only way to make material handling tools like strong crates, stackable pallets, containers, and insulated boxes.

- They can also make plastic storage tanks, gallon barrels, and carboys for holding small to extremely large amounts of water and chemicals.

- Some examples of laboratory and medical supplies made with rotational molding include syringes, oxygen masks, and squeeze bulbs.

- They also make sanitary products such as garbage cans, trash bins, and septic tanks.

- Among other maritime vehicles and equipment for transit and water activities, rock and roll molding machines create rowing boats, canoes, kayaks, and buoys.

Choosing the Proper Rotational Molder Company

To make sure you have the most positive outcome when selecting a rotational molder company, it is important to compare at least 5 companies using our rotational molder directory. Each rotational molder company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each rotational molder company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple rotational molder companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services