Plastic rotational molding is one of many processes by which raw plastic materials are molded into usable products. The market for plastic products worldwide is very extensive. Plastics are used everywhere, and they are available in an enormous variety of shapes, sizes and compositions. Read More…

As a full-service rotational molding company, Roto Dynamics is your source for high quality, custom rotomolded products. Since our inception, we have continued to earn success by closely working with our customers, developing innovative and tailored solutions. We are with you every step of the way, from design and development to production and assembly. For a complete view of our capabilities and ...

We are a custom manufacturer of rotationally molded products. Our state of the art technology creates precise, cost effective and dependable products. Whether your order is large or small, we want to be sure you are satisfied.

Western Industries Plastic Products, LLC, specializes in large-part plastic blow molding. We provide expertise and services in product design, process improvement, and product assemblies. We offer our customers comprehensive services and turnkey opportunities to achieve their specific project goals. We can assist with: R&D, product design, product improvement, and secondary-fixture design. For...

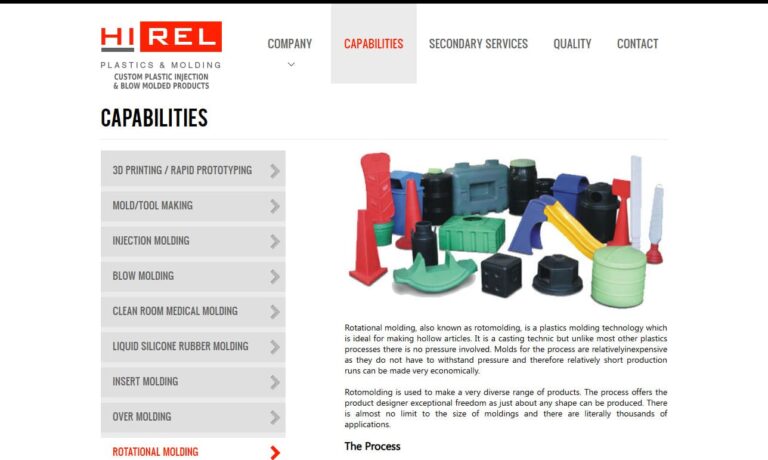

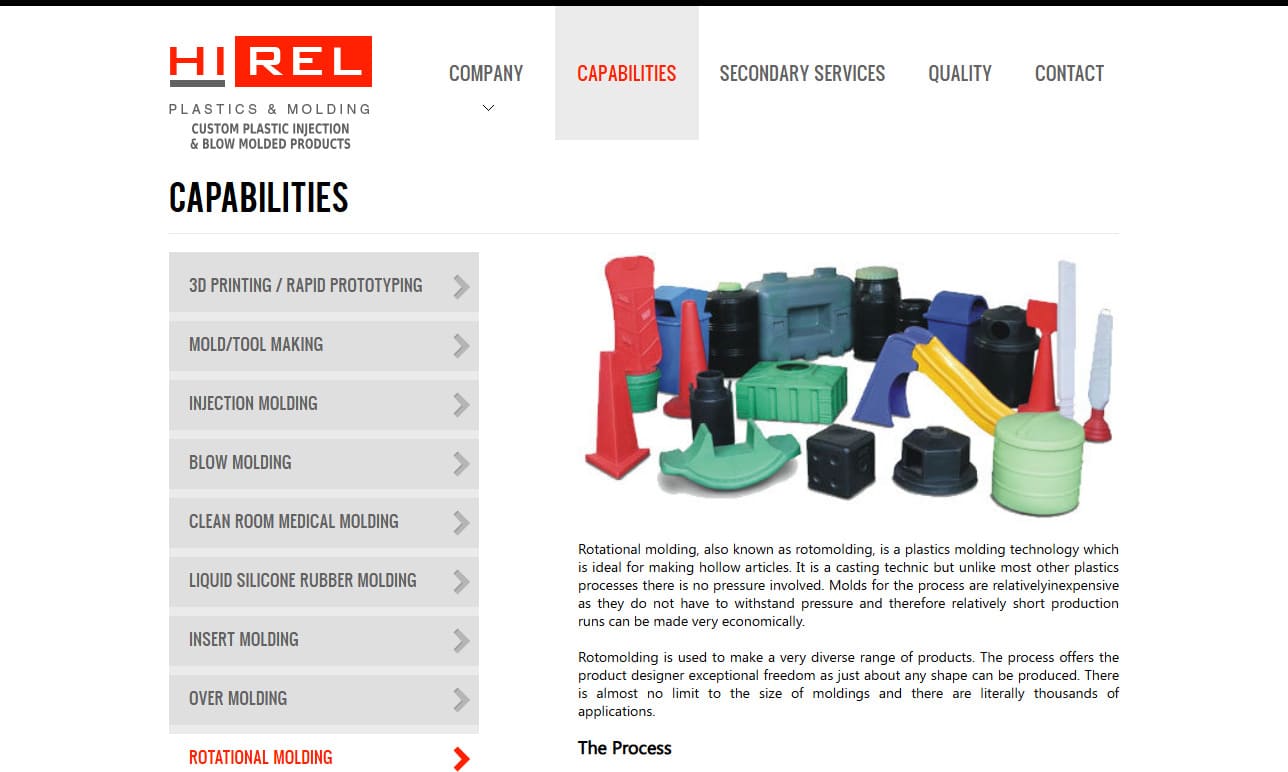

At Hi-Rel Plastics & Molding, we specialize in delivering high-performance solutions through advanced rotational molding. As a team deeply committed to precision and innovation, we bring decades of experience to the design and manufacture of custom rotationally molded products.

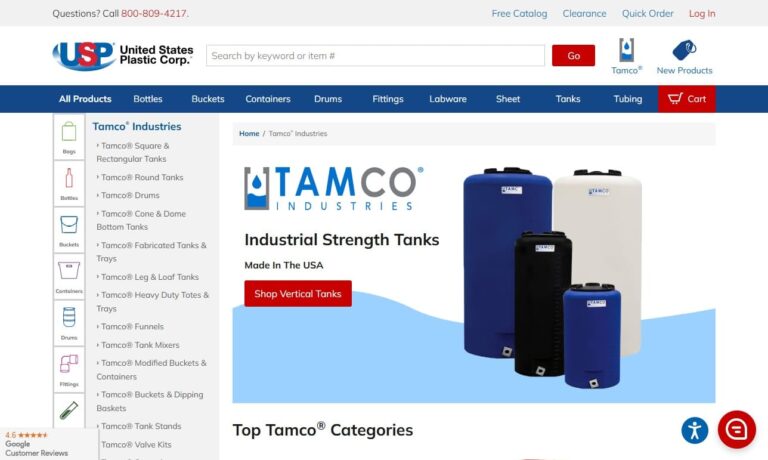

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

More Rotomold Companies

Rotomold refers to the plastic products produced by plastic rotational molding, which are applied throughout industry as containers, equipment parts, light bulb coverings and in many other applications. In commercial settings, furniture, floor mats, lamps, computers, baseboards and storage racks can all be made of plastic or involve plastic components. Consumers make extensive use of plastics in their homes as well. In order to create the wide variety of plastic products on the market, an equally wide variety of plastic formation methods are employed by plastic shaping operations. Rotomolding is among the methods of choice for creating hollow plastic products like tanks and containers.

Rotomolding can be used to create plastic products out of almost any raw plastic material; PVC, nylon, polycarbonate, high and low density polyethylene and PET are just a few of many examples. Rotomoulding is very similar to other plastic formation processes in that it involves the heating of raw plastic materials beyond their melting points in order to make them formable. Once heated beyond their melting points, certain plastics can be shaped, and, once cool, they retain their shape. Plastic extrusion, injection molding and vacuum forming all involve melting thermoplastics in order to form them. Rotomolding involves the collection of raw plastic in a partially open mold. Once full, the mold is sealed and heated.

When the plastic exceeds its melting point, it begins to take the shape of the mold. The mold is then rotated to distribute the plastic so that all of its contours will be covered. By the end of the rotation, the plastic is evenly distributed over all of the surfaces of the mold.

The mold is then cooled by water jets or another cooling method. The cooled plastic product can then be ejected from the mold and either prepared for shipment or sent for additional processing like cutting or painting. From start to finish, the rotomold process takes anywhere from 15 to 90 minutes. It can be used to produce very small products in large quantities or large products in small quantities; rotomolding's versatility is one of its most attractive qualities.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services